How not to make a mistake when I want my board in time

We know very well, it sounds pretty trivial, but it is one of the most common mistakes that has been repeated over and over again, each week, for years. The designer has just finished up his draft, sends it to the production plant and then waits to have the final product available in a couple of days.

Mistake number one is the wait. If your manufacturer is not in touch with you every single day, you are about to have the first problem. Your order is probably already picking up unexpected delay right at the initial intake itself. Good companies usually tend to react within a couple of hours upon receiving the order or quite possibly have online configurators implemented on their websites capable of revealing key inaccuracies.

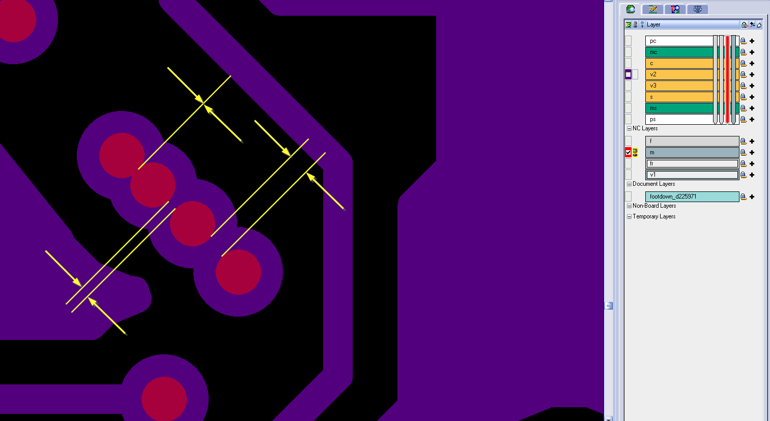

Second dangerous trap is relying on a specific manufacturer. There is a wide range of producers on the market. However, there are even more technologies and combinations of preparations of printed circuit boards available. Practically speaking, no manufacturer is capable of delivering just about any board. But each of them has various restrictions. Some of them offer simpler boards, some offer multilayer ones. Some producers work with copper, some with nickel, silver, gold, or with just some of those materials. Some companies are able to produce rigid-flex boards, whereas some are not. And there are numerous options like this. Therefore it is always a great idea to double check the specifications on the producers website and then address the most appropriate supplier accordingly.

It is very common to work with just one supplier and suddenly you submit a solution to him he is not able to cope with. Or it is also not rare to include several different suppliers in your tenders, however each of them excelling at and focusing only on a specific segment.

„„For instance, we internally use categorization and labelling according to construction categories. We know that we are capable of producing the eighth construction category at the most which labels as 100microns technology. We are unable to manufacture more narrow gaps with a standard process but only with a technological supervision” as explained by Radim Vítek, production manager from Boskovice company Gatema that family holds its place as a respected European producer of printed circuit boards with few were layers.

Apart from these there is a whole range of other mistakes that are in place and that happen during the communication process itself with the producer. It is advisable here to rely on own feeling and intuition about the communication process with staff from the technical research and development department on the side of the producer. Yet this feeling is hard to measure, but is still highly relevant. It is necessary to ask questions whether they are really doing everything in their power to provide you with the best services for timely execution of your order, how professional they are in terms of answering your requests, how willing they are in offering appropriate solutions. Reason for that being the fact that on the market there already is a number of companies being only active as a middleman or intermediary for the business and do not really understand the preparation itself in depth.

It stands to reason that even if you follow these three pieces of advice flawlessly, the game is still not over. A production of printed circuit boards is a really lengthy process and a chain of various steps and is far from being perfect. Whether these are mechanical damages, contamination or various other chemical processes. Even here it is a good idea to follow your gut feeling - and just observe with what frequency these mistakes and flaws your producer makes. And simultaneously, watch with what flexibility the producer is willing to cope with the problems that might arise along the way.

We wish you good luck and no mistakes!

Connect with our specialists