Researchers Developing Ways to introduce Graphene into PCBs for better performance

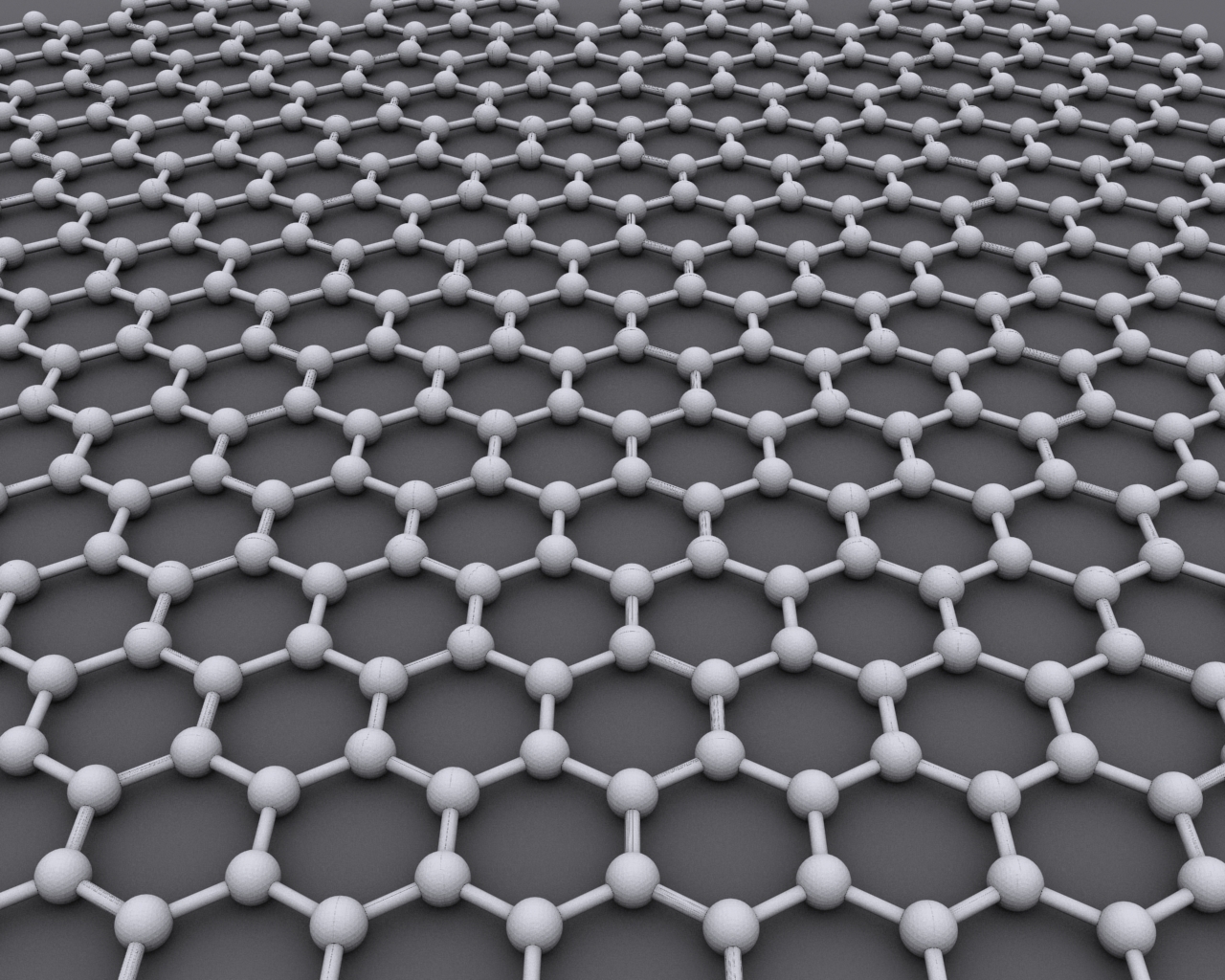

Graphene is a monoatomic material made of carbon hexagons. Graphene, like graphite, is carbon arranged in hexagons through mutual bonds, but the atoms are arranged in only a single layer. Despite its thinness, it is extremely strong and has better electrical conductivity than metals. The material can be deposited on copper, which is the preferred metal for PCBs, by chemical vapour deposition using methane as a precursor. Graphene/Cu kits can then be integrated into standard PCB processing to create advanced circuits. Thanks to its monoatomic structure and high charge mobility, Graphene improves circuit performance at high frequency, which is relevant for both RF systems - such as airborne and automotive radars - and high-speed digital circuits used for 5G communications.

Another exceptional property of Graphene is its thermal conductivity, which is 5 times higher than that of copper. This property allows for a significant improvement in heat dissipation, which is critical for analog high-performance devices such as amplifiers and transmitters. Not only can Graphene be included in circuits as a layer, but Graphene wafers can be mixed into hole-filling epoxy pastes to improve the heat conduction of uncoated intermetallics. In this case, a fine balance between Graphene and epoxy is required, as a high percentage of Graphene in the mixture results in an electrically conductive paste.

The challenge in working with Graphene is to find a way to incorporate the material into Cu layers without damaging its chemical nature through standard processing. For example, Graphene is not resistant to the strong oxidizing agents used in micro-etching prior to plating. Exposed Graphene can contaminate electrolytic baths with carbon or lose its desired properties due to mechanical damage during handling.

So far, researchers have managed to drill, extrude and coat holes in Graphene-containing circuits, making the next phase of Graphene patterning look promising. This work is being carried out in close collaboration with Israeli professors Prof. Doron Naveh (Bar Ilan University), Prof. Oren Regev and Prof. Gennadius Ziskind (both from Ben-Gurion University), and partial results were presented in May 2022 at the International Online Conference on Advances in Graphene Printed Circuit Technology with speakers from academia.

Connect with our specialists